Coring Optimisation Services

Using our experienced personnel that have worked on coring and optimisation projects most recently in Australasia and the Asia Pacific region - we can offer a complete coring optimisation service.

This service can extend from writing or advising on coring tenders, conducting equipment QA/QC pre job load out audits, audits on service providers facilities, and oversight of the planning and execution of coring operations in the office and at the well site on behalf of the operator.

We can also use our experienced engineers to monitor coring operations remotely using the operators real time software. This allows another set of independent experienced eyes to review the data in real time and assist with recommendations during a coring operation.

The SOS team have carried out the optimisation work in recent years for clients such as Inpex (Australia and Indonesia), Woodside (Myanmar, Australia, South Korea), Santos, Quadrant, Apache, AGR and AWE.

Examples of our Optimisation Work:

-

A client recently requested SOS to write the coring ITT, evaluate commercial and technical tender response. By choosing the correct coring system and operator the client acquired the coring service for a highly competitive price.

-

3 x 36m cores were cut with each having 100% recovery in a field that has never been able to fill a core barrel. Our experience and recommendations were then used to further optimise the core barrel lengths and cut 54m cores in the same field with great success.

-

Specialised performed an after action review (AAR) that identified major operational errors including inadequate pre job planning. The findings have changed the way both the operator and the service provider now approach coring operations and pre job planning. Quote from the operator is that "we won't core again without Specialised being involved in our coring operations".

-

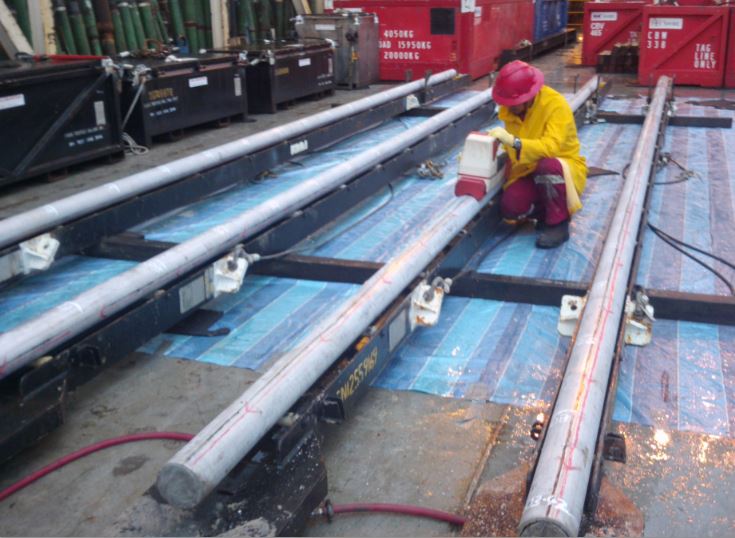

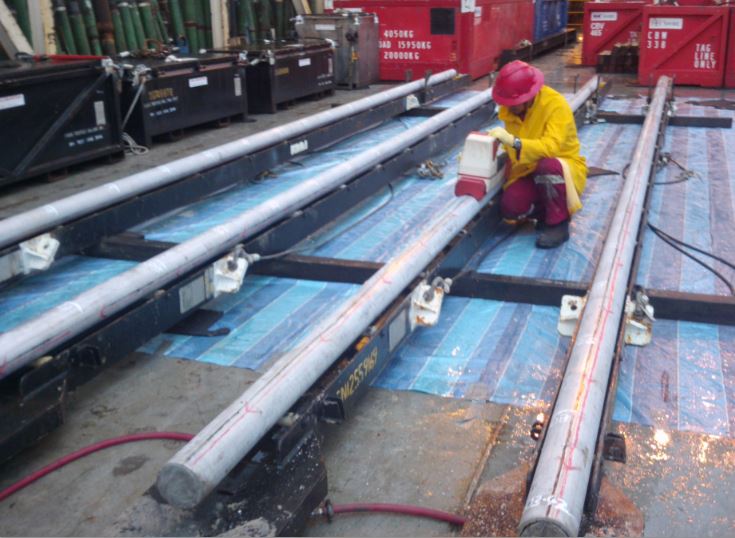

The Specialised team were asked to QAQC the pre job load out and offshore coring operations which resulted in the team recovering 72m of core using the full closure catcher system, which was a record globally.

-

During an international high profile coring operation Specialised was requested by the operator to assist the coring service provider in order to prepare the equipment in time for mobilisation. This included one of our engineers traveling to a remote overseas facility to conduct QA/QC pre mob checks. During these checks our engineer found that some criterial modifications had not been made to the tools which could have caused total loss of core. These issues were resolved in time for the job and the coring was deemed a success.

-

Specialised have run detailed tool failure investigations on behalf of the client. The source of the issue was identified and reported which resulted in a coring company changing their procedures to prevent any future issues.

Why Choose Specialised?

-

To successfully core a well without tool failure or core jamming, the coring service provider has to plan and execute detailed procedures to deliver the client’s requirements. Our coring specialists have witnessed numerous incidents that occur too regularly that are detrimental to the coring operations and can adversely impact the quality of core captured. The issues we can help manage and benefits offered include:

-

Manage service provider’s relative lack of coring experience and allows more time for the Drilling/Geology Team to focus on other operational areas of the well planning.

-

Team of experienced rig site and office based specialists reviewing documentation to ensure all standards, procedures and equipment is ready and in good working order prior to load out and at the rig site.

-

Review contracts, costs and assist in writing the technical sections of tenders to ensure the services offered achieve the best technical and commercial outcome.

-

Review tool build sheets to ensure procedures have been followed, witness connection torque up, gauge stabilisers, physically check loadout package is complete, check that equipment functions correctly prior to load out i.e. gamma loggers, air saws, core preservation equipment, etc.

-

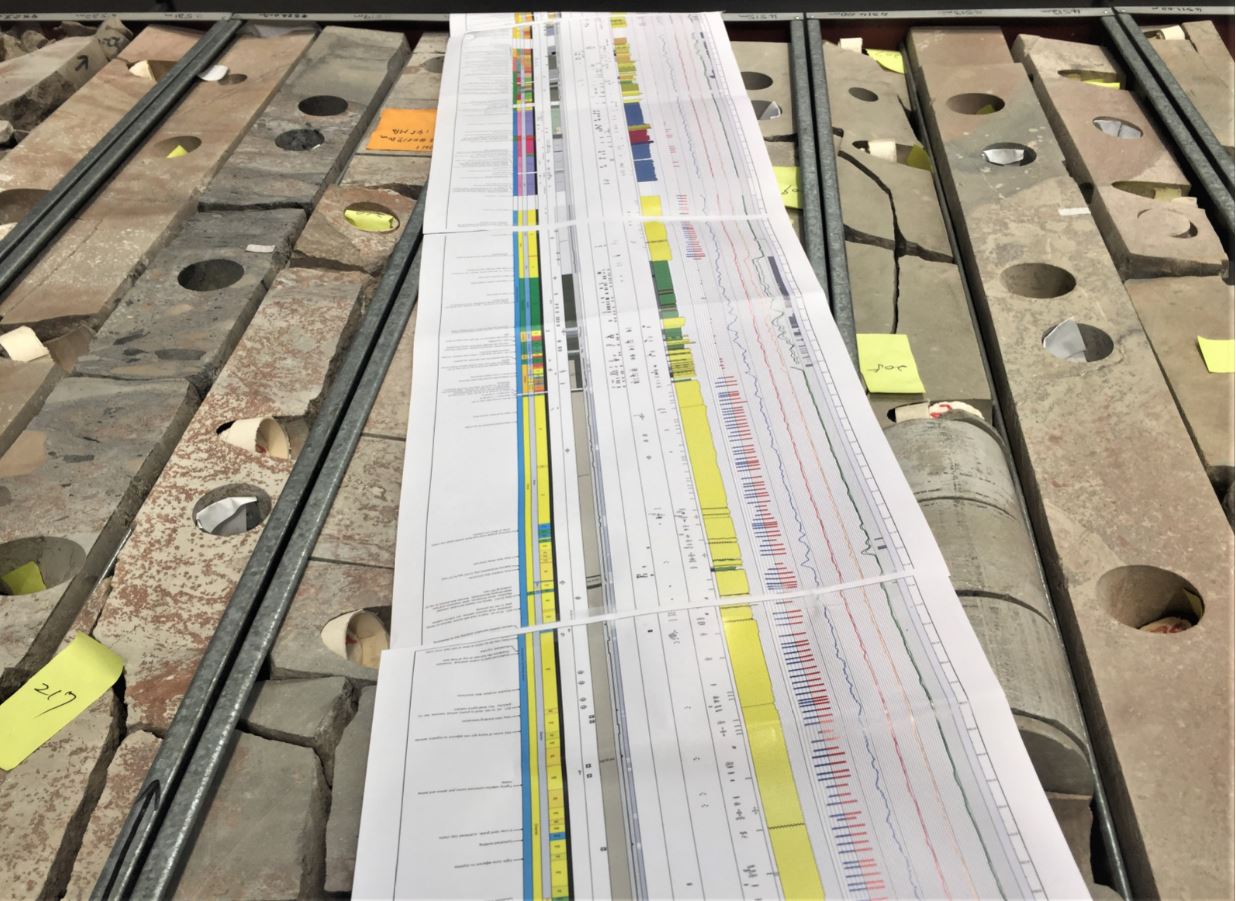

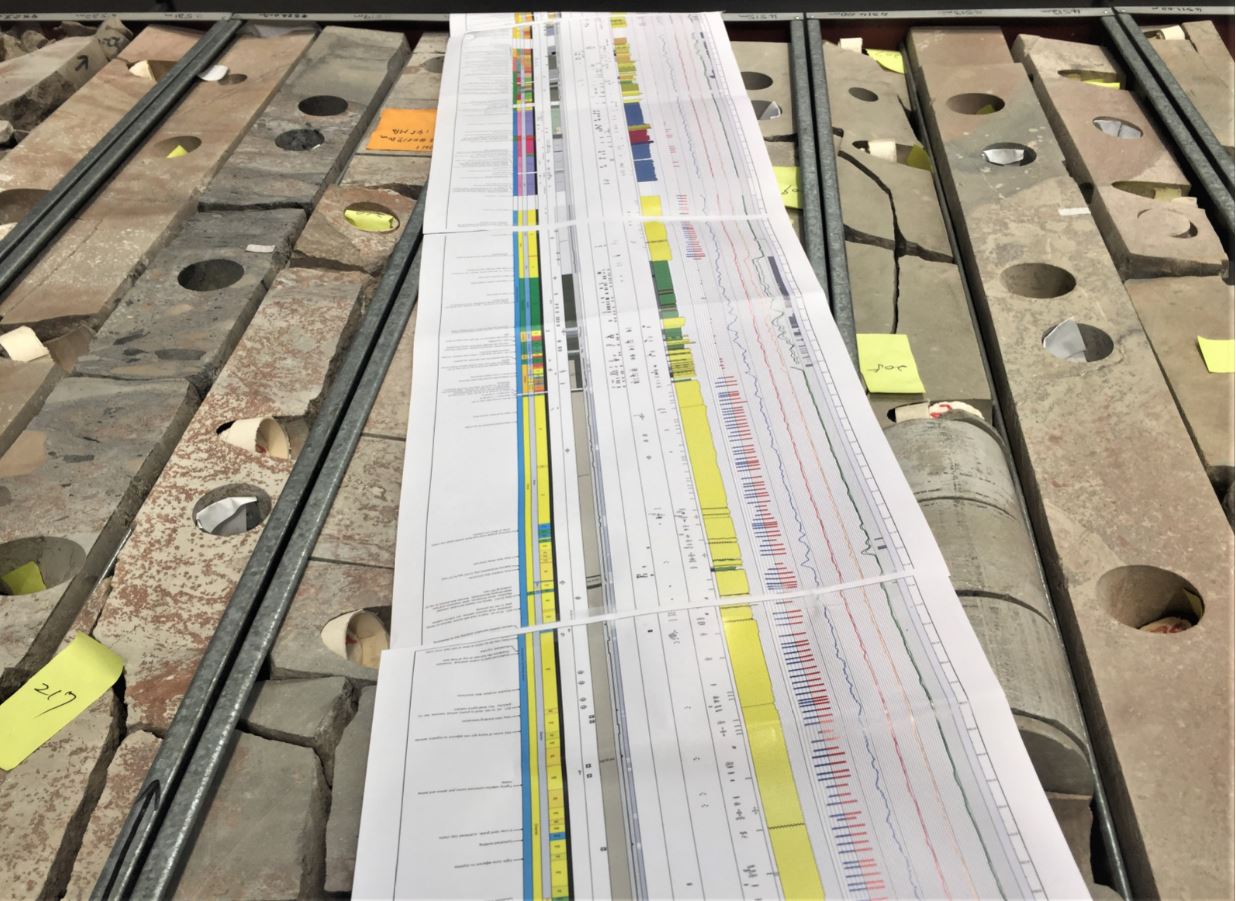

Review coring parameters, offset data, core viewing, coring service providers coring program and provide expert advice on best equipment for a specific application.

-

Advise on corehead choice – too often companies neglect bit technology research and provide re-run coreheads that are not designed to efficiently core the specific formation. Our engineering research will provide the most effective corehead choice for the well objective in addition to reviewing the positives and negatives from using alternative coreheads.

-

Review thermal expansion calculations, oversee coring parameters on the rig floor, provide guidance for on bottom connections and all other coring related operations.

-

Investigate tool failures and provide recommendations for procedural improvements.